WHY HOSE PATCH

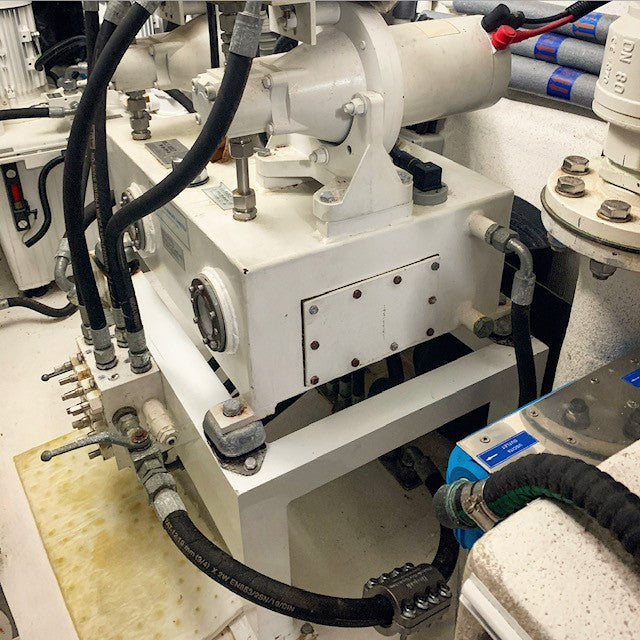

As farmers and contractors, we often experienced significant downtime when a hydraulic hose failed. The process of removing the hose, traveling to town for a replacement and refitting it, could take up to four hours. During weekends, public holidays or when specific fittings were required, this downtime could extend to several days. This inconvenience led us to consider an alternative, creating a temporary solution to stop the leak until a new hose could be fitted. After experimenting with various homemade fixes and finding no suitable products on the market, we decided to design the Hose Patch.

DESIGN

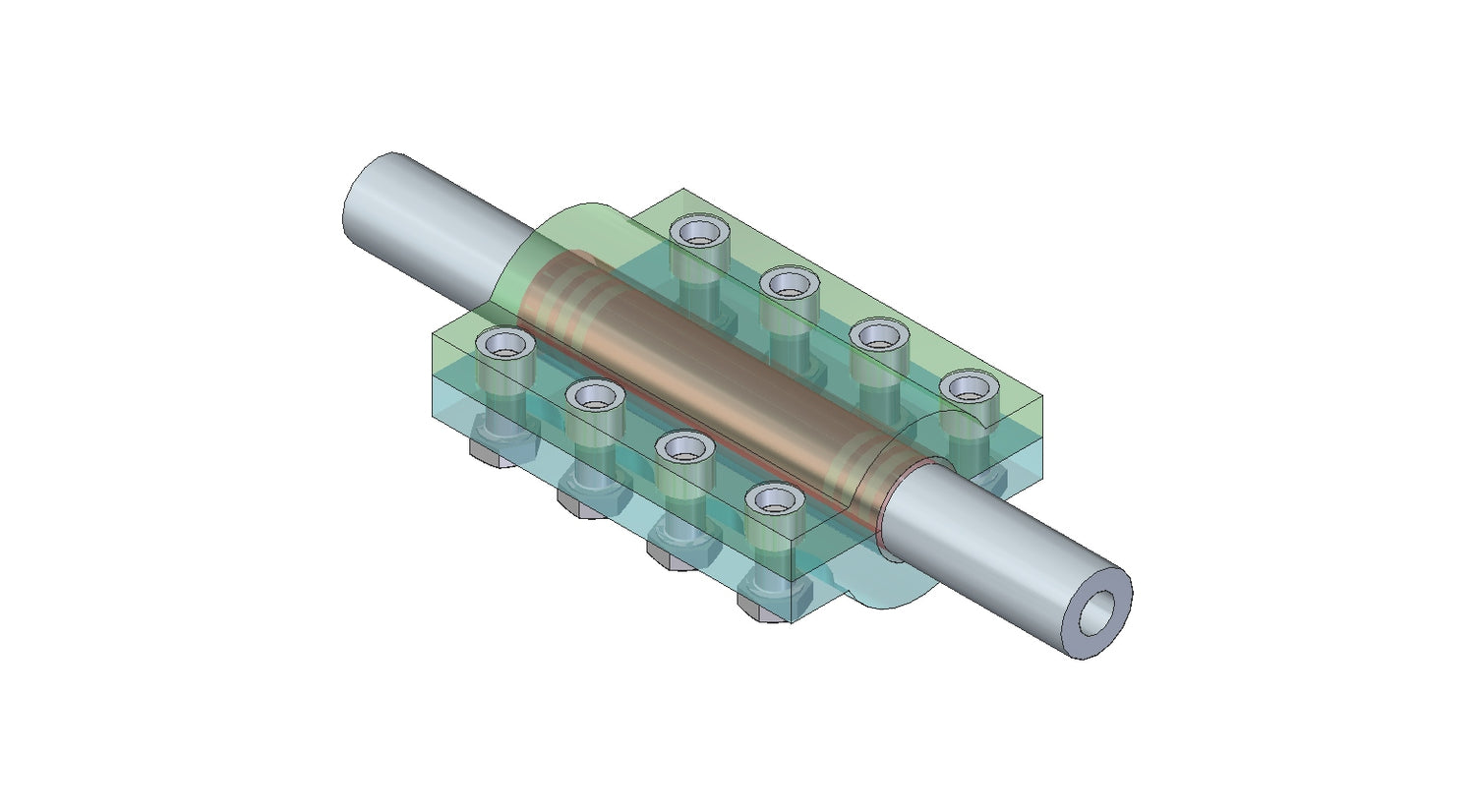

The Hosepatch is engineered for quick, easy and cost effective repairs of hydraulic hoses. Its simple design comprises of two halves made from high quality 316 cast stainless steel and grade 8 bolts. Included in the kit is a joiner for a more robust repair which is also made from high grade 316 stainless steel. The clamp has been designed with ridges to grab hold of the hose and grip the hose with more force. This innovative product is designed to reduce downtime from hours to even days and once your finished you can simply place the hosepatch clamp back in the case ready for its next use.

LONG LASTING

The Hose Patch product is durable and reusable for many years to come due to the high quality material used and the innovative design. Its longevity as a repair solution depends on the specific situation and the condition of the hose being repaired.

It’s a one-time investment that will save time and money for years to come. Its 100% Resuable.

2 WAYS TO USE

1. As a Patch. The clamp can serve as a patch for straightforward repairs, particularly when the hose is in good condition and the pressure is below 2000psi (160 bar). Position the clamp over the hole, ensuring the hole is centered. Tighten the bolts according to the operator's manual, and you're all set. To use as a patch, you will need a 12mm spanner.

2. As a Joiner. The clamp and joiner can be used for more robust repair. The advantages of using as a joiner is that the condition of the hose isn’t important and it can be used for high pressure applications, up to 6000PSI (480 bar). The hose has to be cut and then the joining barb is inserted and the clamp is fitted, making sure the centre of the joining barb is in the centre of the clamp. The bolts are tightened and you’re ready to go. To use as a joiner you will need a cutting device and a 12mm spanner.

OTHER APPLICATIONS

The hosepatch clamp and joiner’s primary use is for hydraulic hoses and therefore all our testing has been aimed at hydraulics. Whilst the hosepatch can be used for many applications such as water line, airlines and chemical line, we cannot recommend these applications and customers must use at their own risk. We have tested on 1sn (1 wire braid), 2SN (2 wire braid), R12 (4 spiral, 4000psi rated), R15 (4 spiral, 6000psi rated) and R7 Thermoplastic. As a patch, the clamp can be used on 2SN, R12 and R15 Hoses. As a joiner it can be used on all the above hoses, passing all testing standards. Unfortunately we can't test on every hose out there, so we cannot guarantee success on every hose made.

SAVE MONEY

While it may be cheaper to repair a hydraulic hose with a Hose Patch than to replace it, the real savings lie in reducing downtime. For example, if you are a contractor charging $90 per hour and a hose fails, four hours of downtime results in a $360 loss. By using a Hosepatch, you can reduce downtime to about 5 minutes and replace the hose when the machine is not in use. Keep the hosepatch clamp somewhere handy ready for its next use.